Energieeffiziente Kaschiertechnik mit Optimierter, innovativer Mikrowellentechnik für dreidimensionale FORmTeile (e-KOMFORT)

In addition to technical specifications and price-performance ratio, comfort is also increasingly a decision criterion for buying a car. Particularly in the context of the trend toward new drive concepts, such as electromobility, the interior is becoming more and more important. High-quality materials and comfort are the interface to the user and help to implement the new vehicle concepts more quickly. For example, up to 9 m2 of technical textiles are installed in cars today, making the car more attractive both visually and haptically. Such decorative materials made out of textile and leather have to be joined to the sometimes complex three-dimensional surfaces by thermal joining, which has so far been very energy- and time-intensive. In addition to the optical and haptic properties, the adhesion and thermal shock resistance of such bonds are also very important.

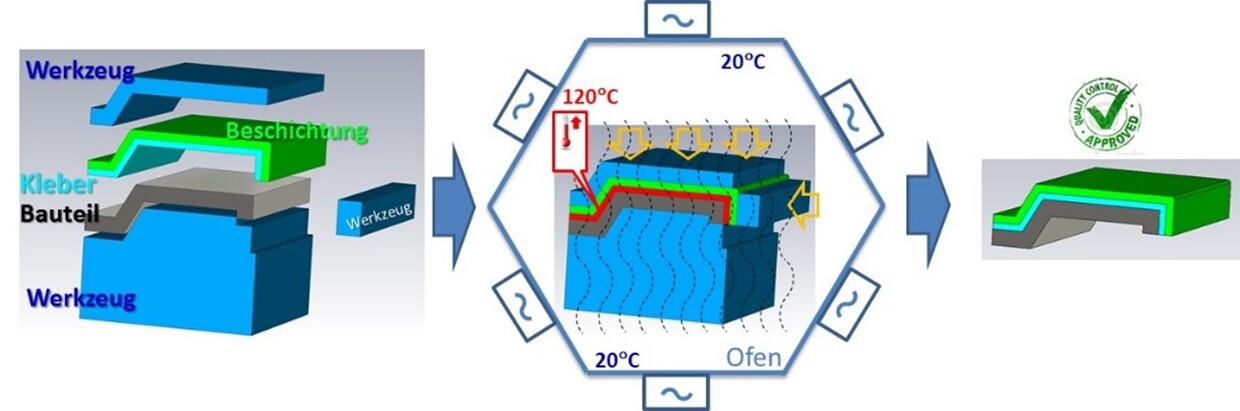

In conventional joining technology, preheated tools transfer the heat for adhesive activation via heat conduction through the surface of the decorative materials or substrate materials, but with suitable microwave technology and suitable adhesives, the heat can be generated directly and selectively in the adhesive. This not only leads to significant energy savings of more than 70%, due to the fact that less material has to be heated, but also to shorter heating cycles and thus greater productivity, because the heat does not have to be transferred through low heat-conducting decor or substrate materials. Furthermore, with such a microwave-assisted technique, temperature profiles can be set by selective heating that allow adhesives to be activated at significantly higher temperatures than the materials to be joined can tolerate without damage. This enables the improvement of joint strength and adhesion resistance and thus an improvement in product quality.

In collaboration with industrial partners, IHM aims to develop and demonstrate an innovative microwave assisted process and tool technology for the energy-efficient lamination of decorative materials, e.g. textile and leather, on three-dimensional surfaces.

Partner:

Carl Meiser GmbH & Co. KG

Greidenweis Maschinebau GmbH & Co. KG

Vötsch Industrietechnik GmbH

Associated Partner:

Eissmann Automotive Deutschland GmbH

Funding: 03ET1576A

Duration: 2018 - 2021