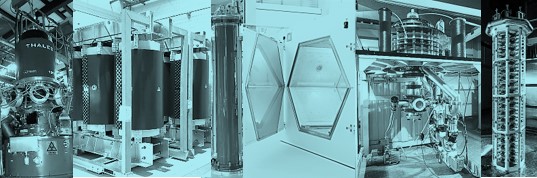

Mechanische Werkstatt des IHM

Performance Profile:

-

Production of complex components with different geometries for apparatus and test facilities in the research sector.

-

Construction and conversion of test facilities and equipment

Manufacturing Process:

-

Materials : Steels, light alloys, heavy alloys, superalloys, plastics

-

Machining : turning, milling, sawing, drilling, grinding

-

Welding : oxyacetylene, electric and inert gas, plastic welding

Technical Equipment:

Turning :

-

Center lathes and bar lathesturning Ø max. 900 mm, turning length max. 1400 mm, spindle passage max. 116 mm

-

NC lathe Weiler E40 (cycle controlled)

turning Ø max. 200 mm, turning length max. 1000 mm, spindle passage max. 54 mm

Milling :

-

Universal milling machines: adjustment travels: X-axis max. 500 mm, Y-axis max. 300mm, Z-axis max. 380 mm

-

NC milling machine Hermle UWF 802 M (line control)Adjustment ranges: X-axis max. 470 mm, Y-axis max. 420 mm, Z-axis max. 380 mm (adjustable angle table)

-

CNC milling machine Deckel FP3NC (continuous path control)

Software support by the CAD/CAM system of Surfcam and AutoCADadjustment travels: X-axis max. 400 mm, Y-axis max. 400 mm, Z-axis max. 400 mm

Drilling :

-

Bench drills

-

Column drilling machine

Sawing :

-

Band saw passage max. 300 mm

-

hacksaw max. saw-Ø 200 mm

-

crosscut saw min. saw-Ø 12 mm to max. saw-Ø 80 mm

Welding :

-

TIG Tungsten Inert Gas Welding

Soldering :

-

Hard and soft soldering

Cutting :

-

Crank plate shears Material thickness VA max. 2 mm

-

Steel max. 2.5 mm

-

non-ferrous metals max. 2.5 mm