Pulsed electric field treatment of microalgae biomass for extraction of valuable intracellular compounds

Microalgae biomass is a promising alternative to agriculturally produced biomass for energetic use. The yield of microalgae biomass per footprint and year is at least twice and the lipid content 10 times higher.

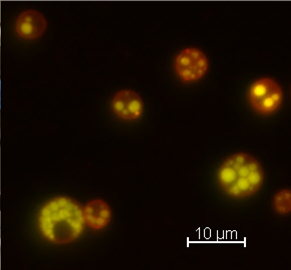

In the framework of the Helmholtz programme „Renewable Energies“, this activity targets on improving downstream processing of microalgae biomass for component recovery and energetic use. Key objective is to improve extraction of intracellular lipids, see intracellular lipid droplets at the fluorescence image, and other valuable substances, i.e. proteins, carbohydrates, minerals, from microalgae by PEF treatment.

For basic investigations, microalgae biomass is cultivated in lab-scale and outdoor photobioreactors at IHM. For cell content and growth monitoring, diverse physical, biochemical and fluorescence diagnostics have been established at IHM.

Recent experimental results reveal, that PEF treatment can increase lipid recovery by green solvent extraction by a factor of 2-4. Also the yield of water-soluble compounds is considerably higher. In addition, the energy-consumption of PEF biomass processing is less than 30% compared to conventional processing.

Uniquely, PEF treatment enables cascade processing of microalgae biomass, i.e. subsequent recovery of several component fractions. Immediately after PEF treatment the water-soluble fraction is released. After that the protein fraction can be recovered. Finally, intracellular lipids still being detained by the cell wall can be extracted by environmental friendly solvents at high yields. Throughout these subsequent extraction steps, excellent biomass separability is preserved, since PEF treatment does not cause cell fragments which commonly impede gravimetric biomass separation.

In close collaboration with the institutes merged within the KIT-Microalgae-Platform, IHM works on identifying best processing routes for economic and energetic valorization of diverse product fractions from microalgae. After separation of high value products, the various residual biomass fractions are screened for most efficient energetic valorization.

Identification of best PEF processing parameters, i.e. electric field amplitude, pulse duration, energy demand and scale-up of PEF processing to a mass-flow on the order of some 100 litres per hour are topics of associated basic research and development efforts.

Microalgae biomass is a promising alternative to agriculturally produced biomass for energetic use. The yield of microalgae biomass per footprint and year is at least twice and the lipid content 10 times higher.

Microalgae biomass is a promising alternative to agriculturally produced biomass for energetic use. The yield of microalgae biomass per footprint and year is at least twice and the lipid content 10 times higher.